The

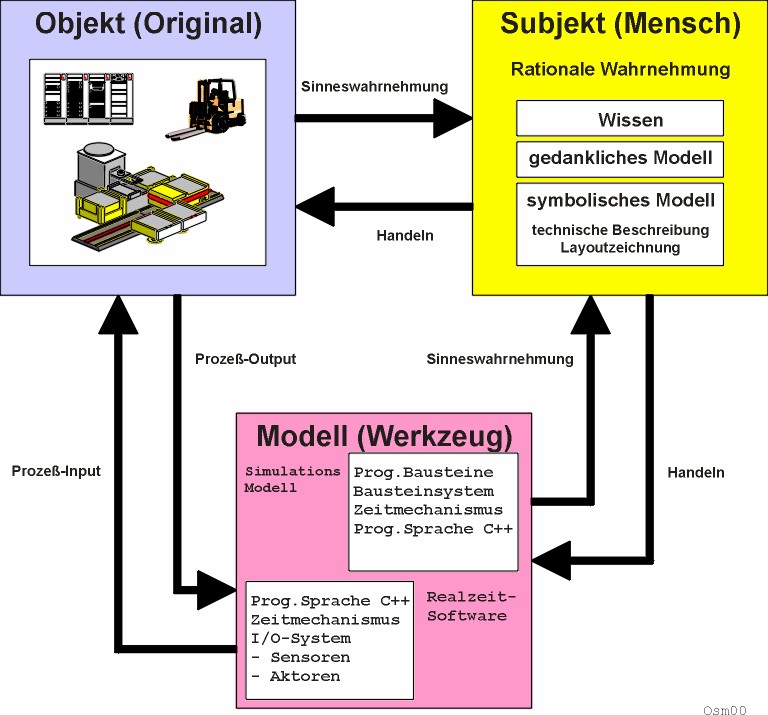

viewpoint is the object, which is the reality in the factory. The

subject, ex:

the factory planner – analyses, fragments and models the

object with the

sensory perception and by the experience of rational perception, with

the

objective to reflect/control the object. A model is developed using

software in

the computer. It serves as a aid for realisation and direct control of

the

object in the form of operative control station.

Simulation

and Logistics are investigated, developed and taught as fundamental

procedures

for the modelling and control of manufacturing plants. The new

realisations

from the factory development help to begin a model for factory

components and

logistic algorithms. Examples of logistic procedures are the

organisation of

tools in flexible production systems, intelligent control of transport

system

without a driver, production control procedure such as Kanban and

Just-in-Time.

The theory,

all the derived methods and tools are put into practise. They are

tested for

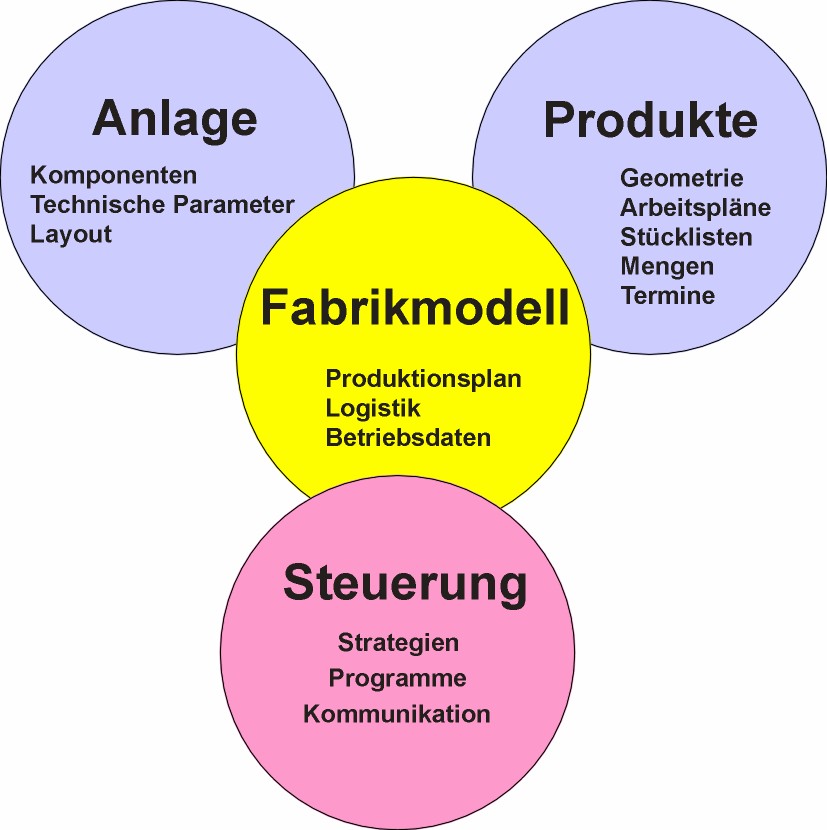

the required services. The main viewpoint is the integration of the

operational

knowledge. In a factory model, all the existing data models from the

parallel

process of the product development and factory development flow

together.

The factory model is the

technical software illustration of the product structure, the factory

structure, and all logistic procedures for the production control.

Transfer

of Technology and Services

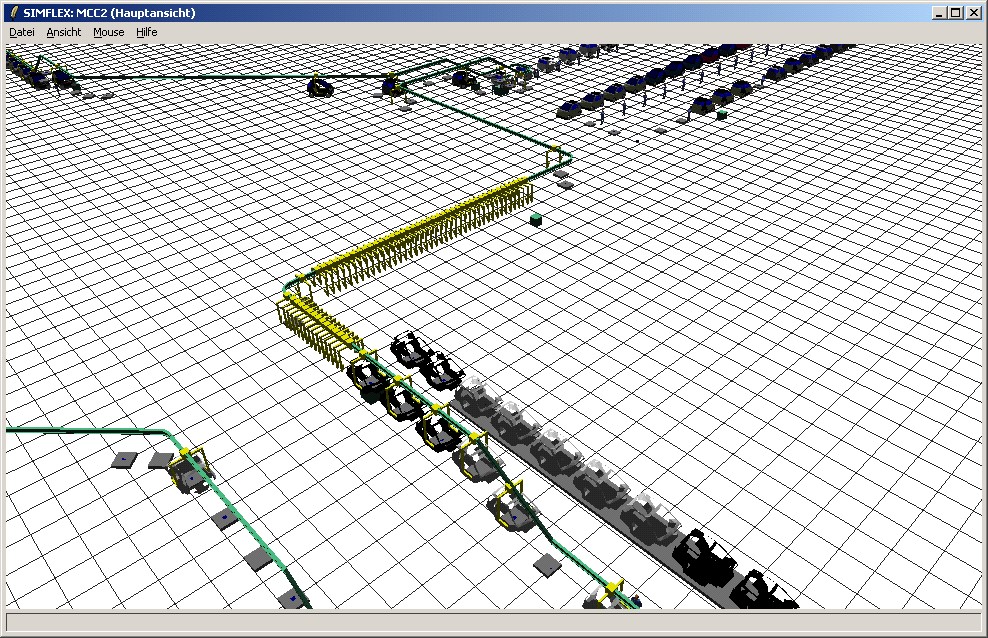

The factory

Simulator SIMFLEX/2 is the result of research, development and

teachings.

SIMFLEX/2 was the only interactive graphic simulator that existed in

1976. In

industry the simulator is used everyday and also developed further (see

SIMFLEX/3).SIMFLEX/2

is not only a tool for factory development but it is also used as a

software

system, an operational control station for the control of technical

plants.

The

department has experiences servicing different industries such as

automobile and

supporting industry, machine tool manufacturer, manufacturers of

package, food

and tobacco processing etc.

Lectures and Know-How

The

contents of the lecture offered by the department is derived from the

research

works and it is oriented towards the requirements of the profile by the

Factory

planners. The students are trained from the first through the last

semester

with sequence of constructive courses. Also, by working for a thesis or

student

job, the student get the opportunity to work independently.

The

lectures offer topics on software technology,

simulation methods, development of Simulators, design and logistics

that is

involved in the factory planning for technical plants.

The

numerous articles, books, industrial seminars & VDI

recommendations (particularly

VDI 3633) has made the know-How publicly available. In this way, the

department

of Production System works in co-operation with the ASIM simulation

research

group.